Imagine this: You’re a mechanic working on a diesel truck, and the engine is sputtering, refusing to cooperate. You’ve checked the fuel lines, the air filter, and the spark plugs (if applicable), but nothing seems to be working. What do you do? The answer lies in the realm of diesel diagnostics.

Understanding the Importance of Diesel Diagnostics

Diesel diagnostics is a crucial process that helps mechanics identify and troubleshoot problems with diesel engines. It involves using specialized tools and software to analyze data from various engine sensors and components. This data provides invaluable insights into the engine’s health, allowing mechanics to pinpoint the root cause of any problems.

Think of it like a detective investigating a crime scene. Diesel diagnostics tools provide the clues – engine data – that mechanics need to solve the “mystery” of why a diesel engine is malfunctioning.

From a mechanic’s perspective, diesel diagnostics are crucial for:

- Quick and accurate troubleshooting: They can save valuable time and effort by pinpointing the problem efficiently.

- Avoiding unnecessary repairs: Instead of replacing parts that may be perfectly fine, mechanics can use diagnostic tools to identify the actual culprit.

- Meeting customer expectations: By efficiently resolving diesel engine issues, mechanics can satisfy their customers and build trust.

From a technical perspective, diesel diagnostics are vital for:

- Engine performance optimization: Diagnostic tools can help tune engines for optimal performance and fuel efficiency.

- Emission control: They can help identify and address potential issues with emissions systems, ensuring compliance with environmental regulations.

- Preventative maintenance: Diagnostic tools can help identify potential problems before they escalate into major repairs, saving both time and money.

From an economic perspective, diesel diagnostics are essential for:

- Reduced downtime: By quickly identifying and resolving problems, diagnostic tools help minimize downtime and keep vehicles running smoothly.

- Lower repair costs: Accurate diagnostics can prevent unnecessary repairs, saving customers money.

- Increased productivity: By keeping diesel engines running optimally, diagnostics help businesses increase their productivity and efficiency.

Unveiling the Secrets of Diesel Diagnostics

What does Diesel Diagnostics involve?

Diesel diagnostics involves a combination of:

- Specialized scan tools: These tools connect to the diesel engine’s onboard computer system and retrieve diagnostic data.

- Software applications: These applications interpret the data retrieved from the scan tools and provide clear and actionable information to mechanics.

- Mechanic expertise: Mechanics need to have a strong understanding of diesel engine systems to interpret the diagnostic data and develop effective repair strategies.

How is Diesel Diagnostics Used?

Here’s a simplified example of how diesel diagnostics can be used:

A diesel truck is experiencing a loss of power. The mechanic connects a scan tool to the truck’s diagnostic port and retrieves data from the engine control unit (ECU). The scan tool reveals a code indicating a faulty fuel pressure sensor. The mechanic then replaces the sensor, and the truck’s power is restored.

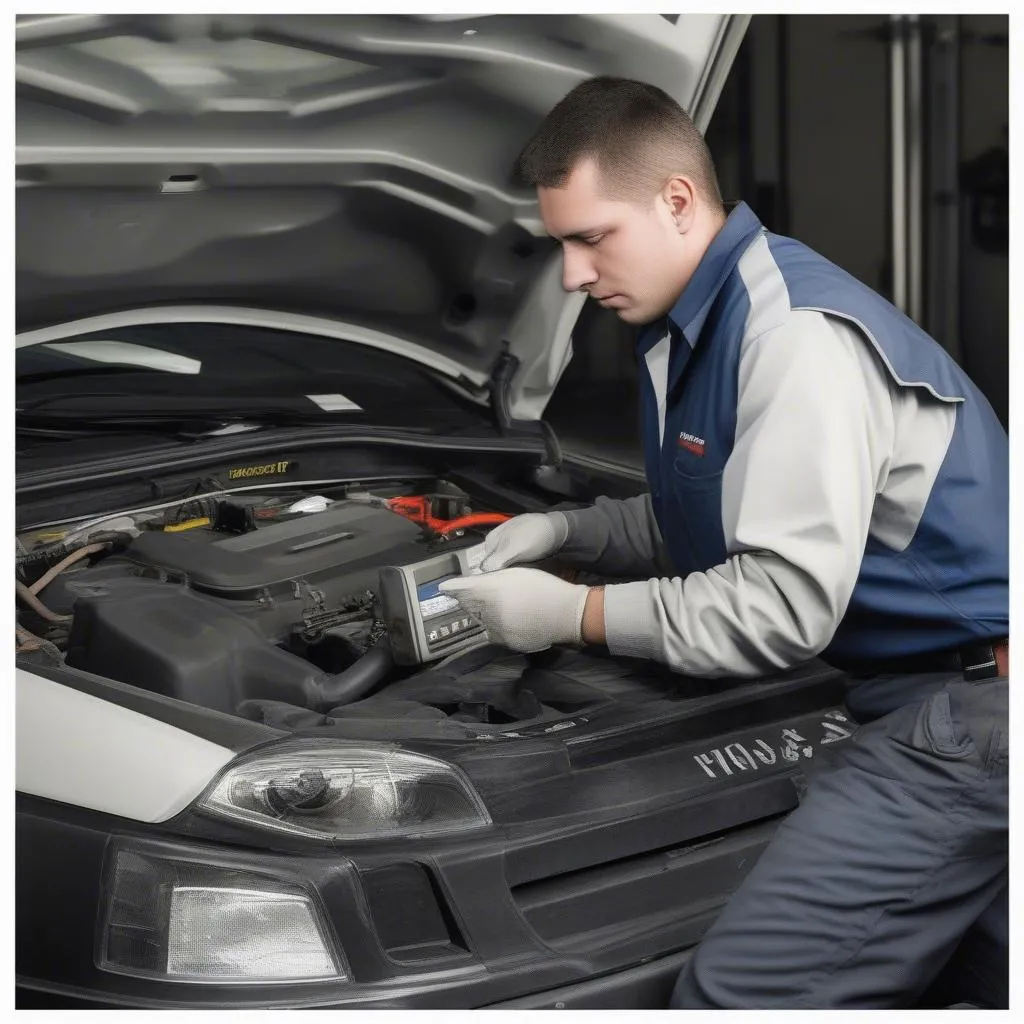

Diesel Diagnostics Scan Tool

Diesel Diagnostics Scan Tool

Common Diesel Diagnostic Procedures

Here are some common diagnostic procedures used for diesel engines:

- Reading diagnostic trouble codes (DTCs): These codes are stored in the ECU and provide information about potential engine problems.

- Monitoring live data streams: This allows mechanics to see real-time sensor readings, such as engine speed, fuel pressure, and coolant temperature.

- Performing cylinder contribution tests: These tests assess the performance of each cylinder, helping to identify problems with individual injectors or combustion issues.

- Analyzing fuel pressure and flow: This helps determine if there are problems with the fuel system, such as clogged filters or faulty injectors.

- Testing exhaust gas emissions: This ensures that the engine is running efficiently and meeting emissions standards.

Top Diesel Diagnostic Tools

The market offers a wide variety of tools for diesel diagnostics, each with its unique capabilities and strengths. Some popular options include:

- Autel MaxiDiag MD805 – A comprehensive diagnostic tool that can be used for both gasoline and diesel vehicles. https://diagxcar.com/autel-maxidiag-md805-work-on-diesel/

- Autel MaxiSys MS906BT – An advanced diagnostic tool with touchscreen capabilities, allowing for efficient data analysis and reporting.

- Launch X431 Pro3 – A powerful diagnostic tool known for its wide vehicle coverage and advanced features.

- Snap-on MODIS Ultra – An industry-leading diagnostic tool known for its robust capabilities and comprehensive coverage.

Diesel Diagnostic Software

Diesel diagnostic software plays a crucial role in interpreting the data retrieved from scan tools. These software packages offer a wide range of features, including:

- DTC lookup and interpretation: Provides definitions and possible causes for trouble codes.

- Live data visualization: Allows mechanics to see real-time sensor readings in various formats.

- Special function testing: Includes functions like injector coding, regeneration control, and DPF cleaning.

Popular diesel diagnostic software includes:

- AutoEnginuity – Known for its user-friendly interface and extensive vehicle coverage.

- FORScan – Primarily used for Ford vehicles, offering advanced diagnostic capabilities.

- JSCAN – A versatile software option with wide vehicle support, including many European and Asian models.

Diesel Diagnostic FAQs

Q: What is the difference between a diesel diagnostic tool and a scan tool?

A: While both diesel diagnostic tools and scan tools are used to retrieve data from a vehicle’s computer system, a diesel diagnostic tool is specifically designed for diesel engines. These tools often offer advanced features for analyzing diesel-specific data and performing specialized tests.

Q: How do I know if my diesel vehicle needs diagnostics?

A: There are several signs that indicate your diesel vehicle might need diagnostics, including:

- Engine warning lights: The “check engine” light or other warning lights can signal problems with the engine or emissions system.

- Performance issues: Loss of power, rough idling, smoke, or difficulty starting.

- Increased fuel consumption: A significant increase in fuel usage can point to engine inefficiencies.

- Excessive noise or vibrations: Abnormal engine noises or vibrations could indicate problems with the engine, fuel system, or other components.

Q: Can I perform diesel diagnostics myself?

A: While some basic diagnostic tests can be performed with DIY tools, professional diesel diagnostics require specialized equipment and expertise. For complex issues, it’s best to consult a qualified mechanic to avoid potentially damaging the engine or making the problem worse.

Q: What are some common diesel diagnostic challenges?

A: Diesel diagnostics can present unique challenges, including:

- Complex engine systems: Diesel engines are more complex than gasoline engines, requiring specialized tools and knowledge.

- Difficult-to-access sensors: Some sensors in diesel engines can be challenging to reach for diagnostics.

- Interpreting data: Understanding the nuances of diesel engine data requires specialized training and experience.

- Keeping up with technology: Diesel engine technology is constantly evolving, requiring mechanics to stay current on diagnostic procedures and tools.

Q: How can I learn more about diesel diagnostics?

A: There are many resources available for learning about diesel diagnostics, including:

- Technical manuals and documentation: Check for resources from manufacturers, automotive associations, and aftermarket parts suppliers.

- Online courses and tutorials: Various online platforms offer comprehensive training on diesel diagnostics.

- Industry certifications: Seeking certifications from reputable organizations, such as ASE (Automotive Service Excellence), demonstrates expertise in diesel engine systems.

- Trade schools and colleges: Enrolling in automotive programs at trade schools or colleges can provide in-depth training in diesel diagnostics.

Q: Is there a specific diesel diagnostic tool for European cars?

A: Yes, there are a number of diagnostic tools specifically designed for European vehicles, often referred to as “Dealer Scanners.” These tools often provide access to a wider range of diagnostic data and functions, allowing for a more in-depth analysis of European diesel engines.

Some popular Dealer Scanners for European cars include:

- Autologic – A popular choice known for its extensive coverage of European vehicles.

- Bosch KTS – A professional diagnostic tool with a wide range of capabilities for European vehicles.

- Hella Gutmann Mega Macs – A comprehensive diagnostic tool with advanced features and a user-friendly interface.

European Diesel Diagnostic Tool

European Diesel Diagnostic Tool

Q: What are some of the most common diesel engine problems?

A: Some common diesel engine problems include:

- Fuel system issues: Clogged fuel filters, faulty injectors, and fuel pump problems.

- Combustion problems: Issues with combustion chamber cleanliness, injector timing, and air intake system.

- Emissions system problems: Clogged DPF filters, faulty EGR valves, and sensor failures.

- Turbocharger problems: Boost leak, impeller damage, and faulty actuator.

- Engine control unit (ECU) problems: Software glitches, sensor failures, and ECU hardware issues.

Q: How can I get help with diesel diagnostics?

A: If you’re facing a complex diesel diagnostic problem, it’s best to consult a qualified mechanic. You can also find valuable information and resources online, such as forums, blogs, and manufacturer websites.

The Future of Diesel Diagnostics

As diesel engine technology continues to evolve, diagnostic tools and techniques will need to adapt to keep pace. Expect advancements in:

- Connectivity: Diagnostic tools will become more connected, allowing for remote access and data analysis.

- Artificial intelligence (AI): AI-powered diagnostics will offer more accurate and efficient problem identification.

- Data analytics: The use of big data and analytics will provide deeper insights into engine performance and health.

Conclusion

Diesel diagnostics are an essential part of maintaining and troubleshooting diesel engines. By understanding the principles of diesel diagnostics and utilizing the right tools, mechanics can efficiently identify and resolve problems, ensuring optimal engine performance, reduced downtime, and satisfied customers.

Want to learn more about diesel diagnostics or need help with your own diesel engine problems?

We encourage you to leave a comment below or reach out to us via WhatsApp at +84767531508. Our team of expert diesel mechanics is available 24/7 to answer your questions and provide support.

Don’t forget to check out our other resources on diesel diagnostics:

Let’s keep the engines running smoothly!