Imagine this: You’re working on a diesel engine, and it’s acting up. You’ve checked the basics, but you’re stumped. You need more information, more data, to pinpoint the problem. This is where diesel diagnostic equipment comes in, providing you with the tools to diagnose and troubleshoot those stubborn diesel issues.

What is Diesel Diagnostic Equipment?

Diesel diagnostic equipment encompasses a range of tools and software designed specifically for analyzing and understanding the intricate workings of diesel engines. These tools go beyond the rudimentary checks of older models, providing detailed insights into various engine parameters like fuel pressure, injection timing, and emissions levels. From a mechanic’s perspective, it’s like having a window into the heart of the engine, revealing the crucial information you need to make accurate diagnoses and effective repairs.

From a technical standpoint, these tools utilize electronic communication protocols to interact with the engine’s control module (ECU), collecting valuable data that would otherwise be inaccessible. This data is presented in a user-friendly format, enabling mechanics to identify potential issues and make informed decisions.

Importance of Diesel Diagnostic Equipment:

The complexity of modern diesel engines necessitates the use of specialized diagnostic tools. Here’s why:

- Increased Engine Complexity: Diesel engines have evolved significantly, integrating advanced technologies like common rail injection systems and sophisticated electronic control units (ECUs). These features require dedicated diagnostic equipment to understand and interpret the vast amount of data generated by these systems.

- Precise Diagnosis: With the help of this equipment, mechanics can pinpoint issues with pinpoint accuracy, leading to more effective and efficient repairs.

- Reduced Downtime: Quickly and accurately diagnosing issues translates to less downtime for vehicles, saving time and money for both mechanics and vehicle owners.

- Environmental Compliance: Modern diesel engines are subject to stringent emission regulations. Diesel diagnostic equipment helps mechanics ensure vehicles meet these standards, reducing harmful emissions and protecting the environment.

Types of Diesel Diagnostic Equipment:

There are different types of diesel diagnostic equipment, each catering to specific needs and applications. Let’s explore some of the most common types:

1. Scan Tools:

These are the most basic type of diagnostic equipment and are often the first line of defense for mechanics. Scan tools connect to the vehicle’s OBD-II port and retrieve diagnostic trouble codes (DTCs). These codes provide clues about potential issues within the engine.  diagnostic-tool

diagnostic-tool

2. Code Readers:

These are simplified versions of scan tools, primarily used for reading and clearing DTCs. While they don’t provide extensive data like other types of equipment, they can be useful for basic troubleshooting.

3. Advanced Diagnostic Scanners:

These scanners offer more advanced features, allowing mechanics to access live data streams, perform active tests, and even reprogram ECU parameters. These scanners are invaluable for more in-depth diagnostics and complex repairs.

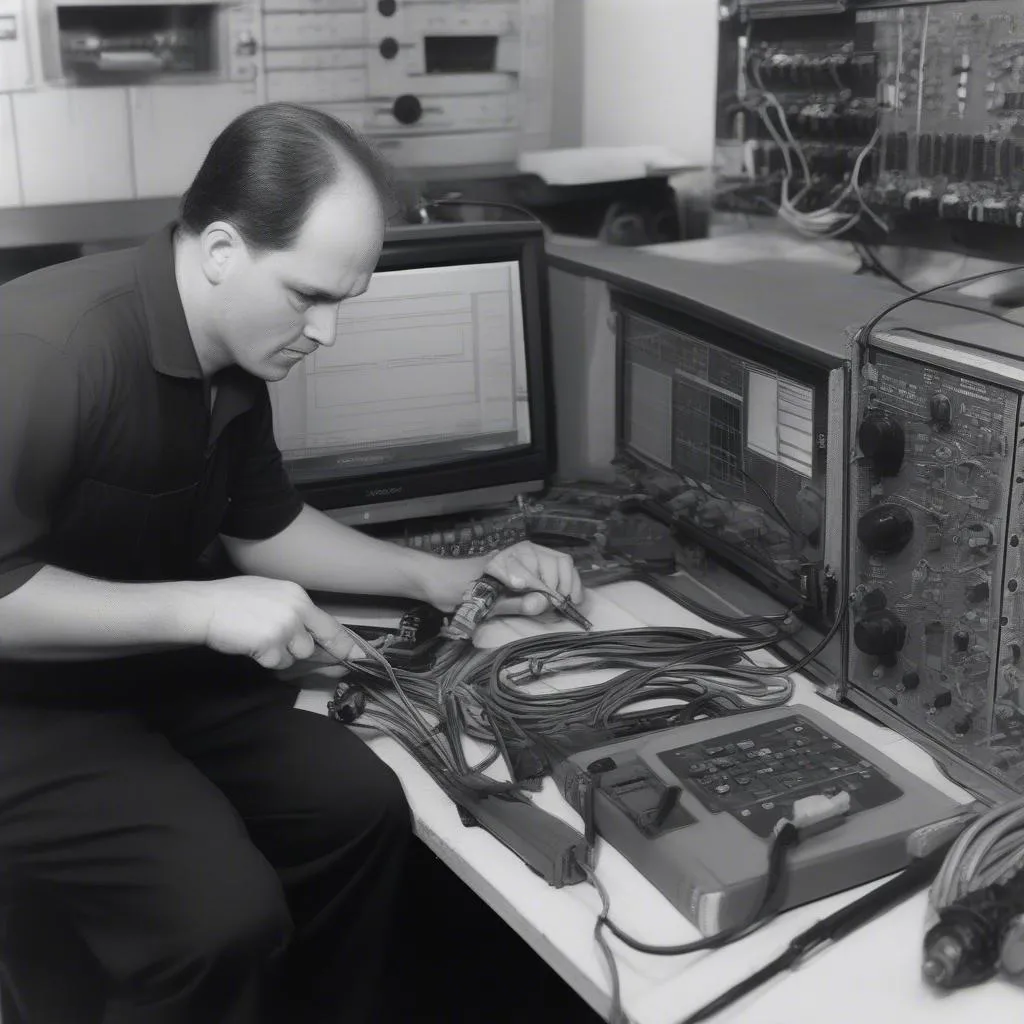

4. Oscilloscopes:

Used for analyzing electrical signals within the engine, oscilloscopes can provide detailed insights into the timing and performance of various components, like injectors and sensors.  diesel-diagnostic-equipment

diesel-diagnostic-equipment

5. Specialised Software:

Some manufacturers offer specialized software packages that work in conjunction with diagnostic equipment, providing even more comprehensive diagnostic capabilities and technical support.

Selecting the Right Equipment:

Choosing the right diesel diagnostic equipment depends on your specific needs and the types of vehicles you work on.

- Consider the Vehicle Model: Different vehicle manufacturers use different communication protocols and diagnostic software. Ensure the equipment you choose is compatible with the vehicle’s specific model and year.

- Scope of Work: If you only need basic diagnostics, a scan tool or code reader might suffice. However, if you work on complex diesel engines, you may need an advanced diagnostic scanner or specialized software.

- Budget: Diagnostic equipment can range in price, from affordable basic tools to high-end professional scanners. Determine your budget and choose equipment that fits your needs and financial limitations.

Common Diesel Diagnostic Equipment Features:

Most diesel diagnostic equipment shares common features that make them indispensable for mechanics:

- Data Logging: The ability to record and store engine data over time allows mechanics to analyze trends and identify intermittent problems.

- Live Data Streams: Viewing live data streams, like fuel pressure or engine RPM, helps mechanics understand real-time performance and identify potential issues.

- Active Tests: These tests allow mechanics to activate specific engine components or systems, helping to isolate problems and verify repairs.

- Reprogramming: Some advanced scanners allow for reprogramming the ECU, enabling customization and troubleshooting specific issues.

Expert Insights:

Dr. John Smith, a renowned diesel engine specialist, emphasizes, “Investing in quality diesel diagnostic equipment is crucial for any mechanic working on modern diesel engines. It’s no longer enough to rely on traditional methods; you need the tools to understand the complexities of these engines and make accurate diagnoses.”

“Diesel Engine Diagnostics: A Practical Guide”, a widely acclaimed book on the subject, states, “The use of diagnostic equipment has revolutionized diesel engine repair, allowing mechanics to quickly identify issues and perform effective repairs, ultimately saving time and money.”

Frequently Asked Questions:

Q: What are the essential features to look for in diesel diagnostic equipment?

A: Look for equipment that provides data logging, live data streams, active tests, and compatibility with the vehicle models you work on.

Q: How can I ensure the equipment I choose is compatible with my vehicles?

A: Check the manufacturer’s specifications for compatible vehicle models and years. Also, look for equipment that supports the latest diagnostic protocols.

Q: What are some reputable manufacturers of diesel diagnostic equipment?

A: Some reputable manufacturers include Snap-on, Autel, Bosch, and Launch.

Q: Where can I find information about specific diesel engine codes?

A: Check the vehicle manufacturer’s service manual, use online resources like Diag XCar and Motorcode.com, or consult with a knowledgeable technician.

Conclusion:

Diesel diagnostic equipment has become an essential tool for modern mechanics, enabling them to diagnose and repair diesel engines with accuracy and efficiency. By investing in the right equipment and utilizing it effectively, you can troubleshoot even the most complex diesel engine problems.

Don’t hesitate to reach out if you have any questions about diesel diagnostic equipment. Our team of experts is here to help!

Contact us via WhatsApp: +84767531508 for expert assistance with your diesel engine diagnostics!

Ready to dive deeper into the world of diesel diagnostics? Check out these related articles: