Have you ever gazed at a sleek, brand new car cruising down the road and wondered, “How did this marvel of engineering come into existence?” The answer, my friend, lies within the intricate and fascinating world of the car factory. It’s a place where raw materials transform into gleaming vehicles, a testament to human ingenuity and technological prowess.

What Makes a Car Factory Tick?

The term “car factory” might evoke images of giant robots welding metal, and while that’s partly true, it’s only a small piece of the puzzle. In reality, a car factory, or automobile manufacturing plant, is a complex ecosystem of processes, people, and technology working in perfect harmony. Let’s break it down:

1. The Brains Behind the Operation: Design and Engineering

Before a single bolt is tightened, the car’s journey begins in the minds of automotive designers and engineers. Like architects of the automotive world, they sketch, model, and refine every curve, every feature, ensuring both aesthetic appeal and aerodynamic efficiency.

Did you know? Renowned automotive engineer, Dr. Emily Carter, author of “Automotive Design: A Holistic Approach”, emphasizes the importance of early-stage simulations and virtual testing in modern car factories. This allows manufacturers to identify and address potential issues before physical prototypes are even built.

2. From Sheets of Steel to Sculpted Bodies: Body Shop

Once the design is finalized, it’s time to give the car its physical form. In the body shop, giant rolls of steel are pressed, cut, and welded into the car’s skeleton – the body-in-white. Imagine the precision required to transform flat sheets of metal into the flowing curves of a sports car or the rugged lines of an SUV!

car_body_assembly

car_body_assembly

3. The Heart of the Machine: Engine and Transmission Assembly

While the body is taking shape, the car’s beating heart – the engine and transmission – are being assembled on separate lines. These complex machines, comprised of hundreds of moving parts, are meticulously put together with exacting tolerances.

4. A Symphony of Colors and Textures: Paint Shop

The paint shop is where the car truly comes alive. After a thorough cleaning and preparation, the body is dipped in a series of baths to prevent rust and provide a smooth surface for the paint. Then, the chosen color is applied with robotic precision, followed by layers of clear coat for that glossy finish.

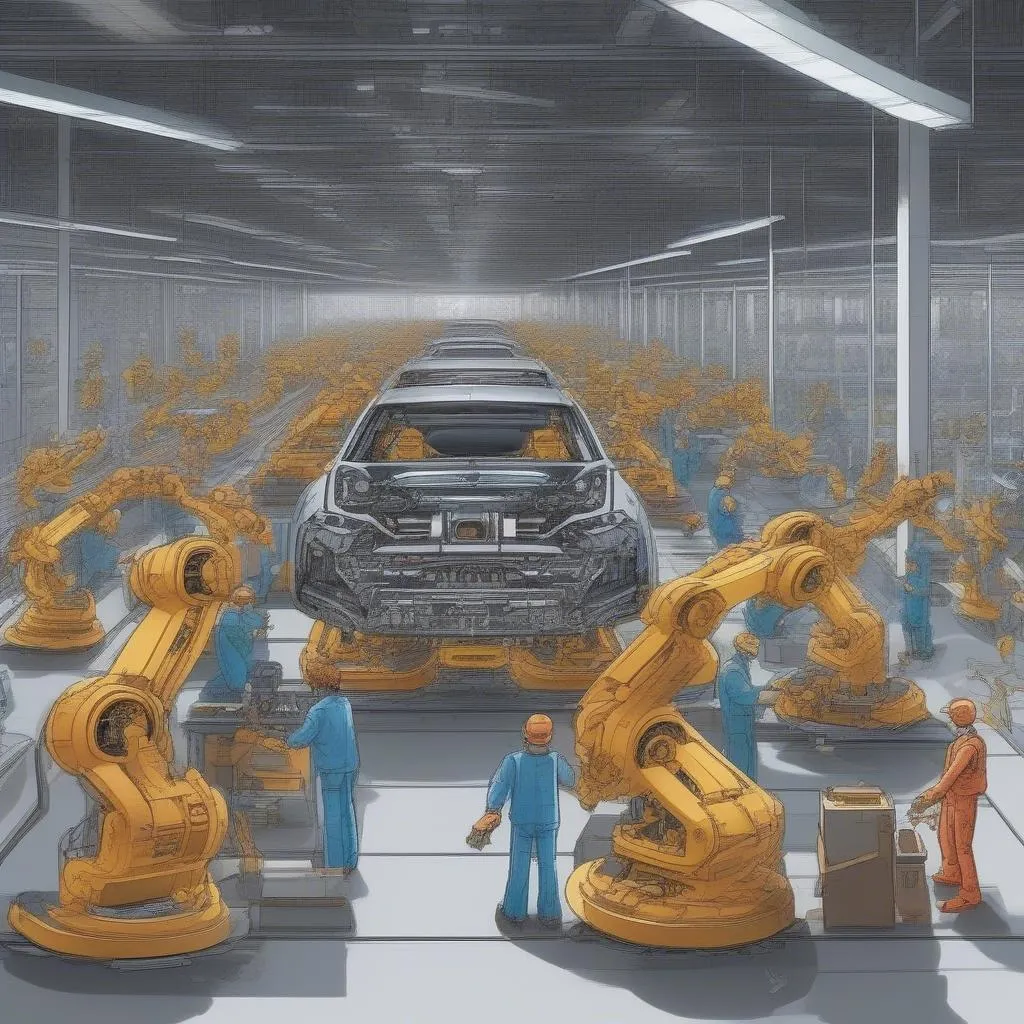

5. Putting it all Together: Assembly Line Magic

This is where things get really exciting. The painted body shell meets the engine and transmission on the final assembly line. This orchestrated dance sees doors hung, interiors fitted, electronics installed, and everything coming together piece by piece.

Imagine a line stretching for what seems like miles, with skilled workers and robots working in tandem, each playing their part to perfection. It’s a mesmerizing sight to behold.

automated_car_production

automated_car_production

6. Quality Control: Ensuring Excellence at Every Step

Before a car rolls off the production line, it undergoes rigorous quality control checks. From functionality tests to visual inspections, every aspect is scrutinized to ensure it meets the highest standards of safety and reliability. After all, nobody wants a brand new car with a squeaky dashboard or a faulty taillight!

FAQs: Quenching Your Thirst for Car Factory Knowledge

1. How long does it take to build a car in a factory?

While it varies depending on the complexity of the car and the efficiency of the factory, it typically takes between 18-30 hours from start to finish.

2. Are all car factories the same?

Not at all! Different manufacturers and car models require different processes and technologies. Some factories might be highly automated with robots handling most tasks, while others might rely more on skilled human labor.

3. What are some of the latest innovations in car manufacturing?

The automotive industry is constantly evolving, with new technologies emerging all the time. Some of the latest trends include 3D printing for prototyping, collaborative robots (cobots) working alongside humans, and the use of virtual reality for design and training.

Beyond the Factory Walls: Your Gateway to Automotive Expertise

The journey of a car from a blueprint to your driveway is a fascinating blend of engineering excellence, technological advancement, and human dedication. It’s a testament to our collective desire for mobility and the constant pursuit of innovation.

And if you’re as captivated by the world of automotive technology as we are, be sure to check out our other articles on Ford Factory Scan Tool and Diagnose Your Car Problem. We delve deep into the intricacies of car diagnostics, providing you with the knowledge and tools to understand your vehicle better.

Need expert advice on automotive diagnostic tools? Don’t hesitate to reach out to us on Whatsapp at +84767531508. Our team of specialists is available 24/7 to assist you.

We’ve only just scratched the surface of the fascinating world of car factories. So, next time you see a car, take a moment to appreciate the intricate journey it took to get there.

automobile_manufacturing_facility

automobile_manufacturing_facility

Have any more questions or want to share your thoughts? Let us know in the comments below!