Imagine this: you’re driving down the highway, and suddenly your car starts sputtering and jerking. You pull over, check under the hood, and see nothing out of the ordinary. You try restarting the engine, but it just won’t turn over. What could be the problem?

One possibility is a faulty EVAP (evaporative emission control) system. The EVAP system is responsible for capturing and storing fuel vapors that escape from the fuel tank. These vapors are then routed back to the engine to be burned. If the EVAP system isn’t working properly, it can lead to a number of problems, including reduced fuel economy, engine performance issues, and even engine damage.

What is a Bidirectional Scan Tool EVAP Actuator?

A bidirectional scan tool is a diagnostic tool used by mechanics to test and diagnose automotive systems. It can be used to communicate with the vehicle’s computer system (ECU) to retrieve diagnostic trouble codes (DTCs), monitor live data streams, and perform various other tests.

The EVAP actuator is a component of the EVAP system that controls the flow of fuel vapors. It is typically a solenoid valve that is activated by the ECU. The bidirectional scan tool can be used to test the EVAP actuator by activating and deactivating the solenoid valve and observing the results.

Understanding the Importance of the Bidirectional Scan Tool EVAP Actuator

The EVAP actuator is a critical component of the EVAP system, and a faulty EVAP actuator can lead to a variety of problems. For example, if the EVAP actuator is stuck open, fuel vapors may leak out of the fuel tank and into the atmosphere. This can result in a reduction in fuel economy, as well as environmental damage. On the other hand, if the EVAP actuator is stuck closed, fuel vapors may build up in the fuel tank and create a pressure buildup. This can lead to a number of problems, including engine performance issues, fuel leaks, and even a fire hazard.

How a Bidirectional Scan Tool Diagnoses EVAP Actuator Issues

When using a bidirectional scan tool to diagnose EVAP actuator problems, mechanics will typically start by retrieving any diagnostic trouble codes that are related to the EVAP system. These codes can provide valuable information about the nature of the problem. For example, a DTC that indicates a “stuck open EVAP actuator” will tell the mechanic that the EVAP actuator is not functioning properly.

Once the DTCs have been retrieved, the mechanic will then use the bidirectional scan tool to perform a number of tests on the EVAP system. These tests may include monitoring live data streams, activating and deactivating the EVAP actuator, and performing a pressure test on the EVAP system.

For example, a mechanic might use a bidirectional scan tool to test the EVAP actuator by activating and deactivating the solenoid valve and observing the results. If the solenoid valve opens and closes as expected, then the EVAP actuator is likely working properly. However, if the solenoid valve does not open or close, then the EVAP actuator is likely faulty and needs to be replaced.

A visual representation of how a bidirectional scan tool can be used to diagnose EVAP actuator issues can be found below:

Using a bidirectional scan tool to diagnose EVAP actuator issues

Using a bidirectional scan tool to diagnose EVAP actuator issues

How to Use a Bidirectional Scan Tool EVAP Actuator

To use a bidirectional scan tool to test the EVAP actuator, you will first need to connect the scan tool to the vehicle’s OBDII port. Once the scan tool is connected, you will need to select the EVAP system from the scan tool menu.

The next step is to use the scan tool to activate and deactivate the EVAP actuator solenoid valve. This can be done by selecting the appropriate command from the scan tool menu. You will then need to observe the results of the test.

If the EVAP actuator is functioning properly, the solenoid valve should open and close as expected when the scan tool commands are sent. If the solenoid valve does not open or close, then the EVAP actuator is likely faulty and needs to be replaced.

Common EVAP Actuator Problems

Here are some of the common EVAP actuator problems that can be diagnosed using a bidirectional scan tool:

- Stuck open EVAP actuator: This is a common problem that can occur when the solenoid valve in the EVAP actuator becomes stuck in the open position. This can lead to fuel vapors escaping from the fuel tank and into the atmosphere.

- Stuck closed EVAP actuator: This is another common problem that can occur when the solenoid valve in the EVAP actuator becomes stuck in the closed position. This can lead to a buildup of pressure in the fuel tank, which can damage the fuel tank or even cause a fire hazard.

- Faulty EVAP actuator solenoid valve: The solenoid valve in the EVAP actuator can fail, which can prevent the EVAP actuator from working properly.

- Damaged wiring: The wiring to the EVAP actuator can become damaged, which can prevent the EVAP actuator from receiving the correct signals from the ECU.

EVAP Actuator Troubleshooting with Bidirectional Scan Tool

When troubleshooting an EVAP actuator problem, a mechanic will typically start by inspecting the EVAP actuator for any signs of damage. They will then use a bidirectional scan tool to test the EVAP actuator and look for any signs of a problem.

If the scan tool reveals that the EVAP actuator is faulty, the mechanic will need to replace it. If the scan tool does not reveal any problems with the EVAP actuator, the mechanic may need to inspect other components of the EVAP system, such as the fuel tank, the charcoal canister, or the purge valve.

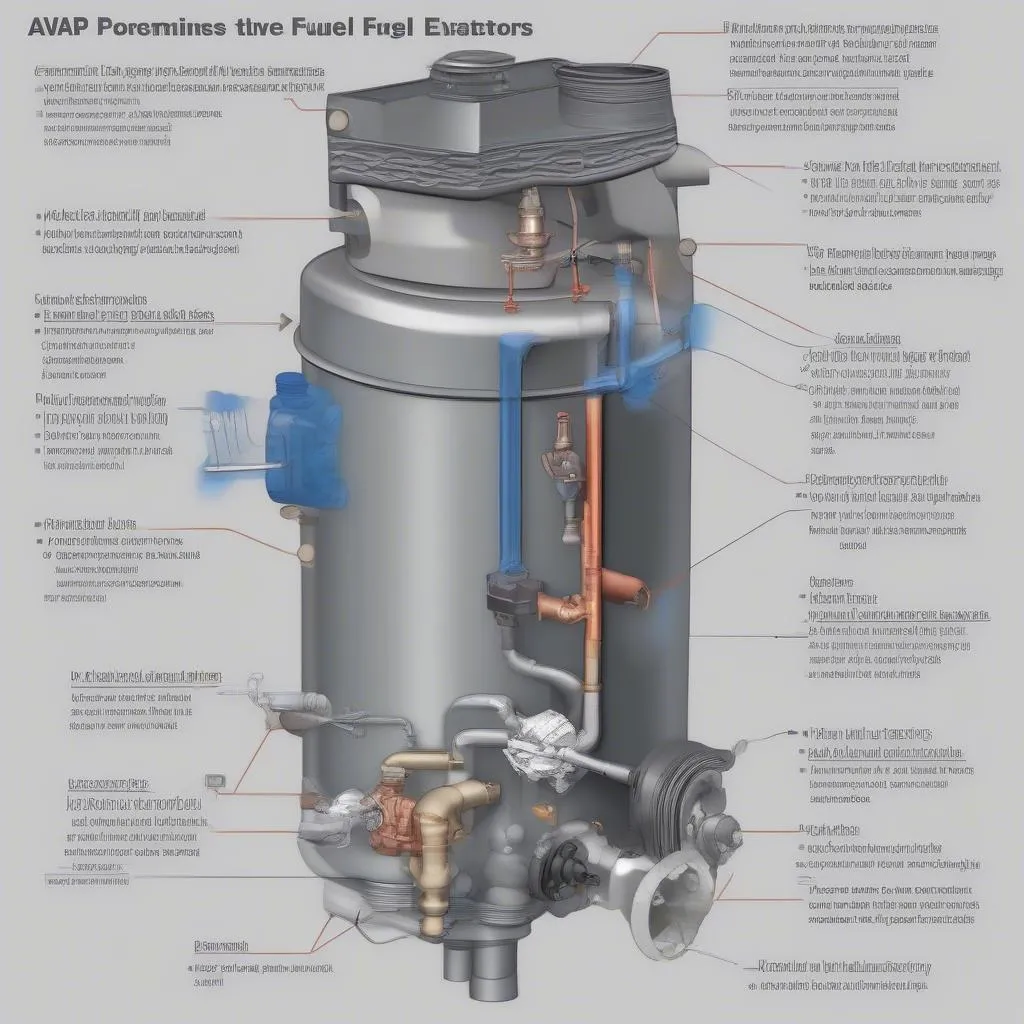

The image below illustrates the location of common EVAP system components that a mechanic might inspect during troubleshooting:

Components of the EVAP system

Components of the EVAP system

Conclusion

Bidirectional scan tools play a crucial role in diagnosing EVAP actuator issues. By using a bidirectional scan tool, mechanics can quickly and accurately test the EVAP actuator and determine if it is working properly. This can help to ensure that the EVAP system is functioning properly and that fuel vapors are not escaping from the fuel tank. If you suspect that your EVAP actuator may be faulty, it is important to have it inspected by a qualified mechanic.

If you need help with installing any of these diagnostic tools, feel free to contact us at +84767531508. We offer 24/7 support and are committed to helping you keep your car in tip-top shape.