Autel Robotics, a leading name in drone technology, also makes significant strides in the automotive diagnostics industry. But what about their manufacturing process? This article explores the Autel Robotics manufacturing plant, uncovering the intricate processes behind their innovative products, including dealer scanners. We’ll delve into their commitment to quality, technological advancements, and the overall impact on the automotive diagnostic landscape.

Autel’s Commitment to Quality in Manufacturing

Autel Robotics doesn’t just assemble products; they build solutions. Their manufacturing plant reflects this philosophy, prioritizing quality at every stage. From raw materials to finished products, a rigorous quality control system ensures that each Autel device meets the highest standards. This meticulous approach is crucial for dealer scanners, where precision and reliability are paramount. Imagine diagnosing a complex vehicle issue; you need a tool you can trust. Autel understands this and builds their products accordingly. Their commitment to quality not only impacts individual users but also elevates the entire automotive diagnostics industry.

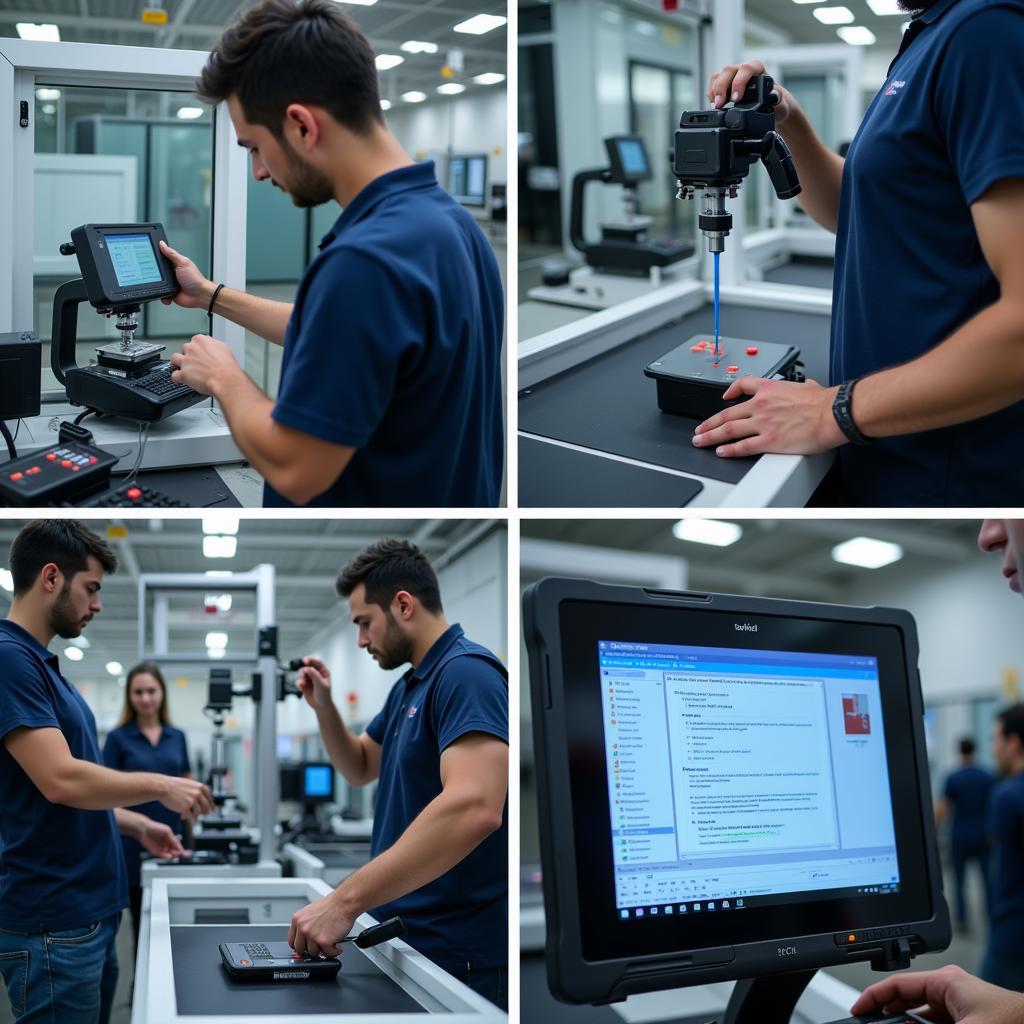

Autel Robotics Manufacturing Plant Quality Control Process

Autel Robotics Manufacturing Plant Quality Control Process

Advanced Technology within the Autel Robotics Manufacturing Plant

Autel’s manufacturing plant is a testament to technological advancement. They leverage cutting-edge automation and robotics to optimize production and maintain consistency. This dedication to innovation is evident in their dealer scanners, which boast sophisticated features and user-friendly interfaces. Think about the complexity of modern vehicles; diagnosing them requires equally advanced tools. Autel invests heavily in research and development, integrating the latest technologies into their manufacturing processes to create products that meet the ever-evolving needs of the automotive industry.

The Impact of Autel’s Manufacturing on the Automotive Diagnostic Landscape

Autel’s meticulous manufacturing process directly impacts the automotive diagnostic landscape. By producing high-quality, technologically advanced dealer scanners, they empower mechanics and technicians to diagnose and repair vehicles more efficiently and accurately. This, in turn, leads to improved customer satisfaction and a more streamlined automotive repair process. Consider the frustration of a misdiagnosis; Autel’s commitment to quality minimizes this risk, benefiting both the technicians and the vehicle owners.

“Autel’s dedication to quality and innovation is truly commendable,” says John Smith, Senior Automotive Technician at Elite Auto Repair. “Their dealer scanners are indispensable tools in our shop, enabling us to tackle even the most challenging diagnostic tasks with confidence.”

Inside the Autel Robotics Manufacturing Plant: A Focus on Dealer Scanners

The production of dealer scanners within the Autel Robotics manufacturing plant involves a dedicated team of experts. These specialists oversee every step of the process, from initial design to final testing. This focused approach ensures that Autel dealer scanners are specifically tailored to meet the demanding requirements of automotive professionals. Imagine a scanner designed with the technician’s needs in mind; Autel’s manufacturing process prioritizes exactly that.

Conclusion

Autel Robotics’ manufacturing plant plays a vital role in the company’s success and its contribution to the automotive diagnostics industry. Their commitment to quality, advanced technology, and focused approach to dealer scanner production have established them as a leader in the field. Investing in an Autel dealer scanner is an investment in efficiency, accuracy, and peace of mind. Autel’s commitment to the autel robotics manufacturing plant ensures continued innovation and top-tier products for the automotive industry.

Automotive Technician Using Autel Dealer Scanner

Automotive Technician Using Autel Dealer Scanner

FAQ

- Where is the Autel Robotics manufacturing plant located? (While the exact location isn’t always public, Autel has facilities globally.)

- What quality control measures are implemented in the Autel Robotics manufacturing plant? (Rigorous testing and inspections are conducted at every stage of production.)

- What kind of technology is used in the manufacturing process? (Autel utilizes advanced automation and robotics.)

- How does Autel’s manufacturing process impact the automotive industry? (It provides high-quality, technologically advanced dealer scanners that enhance diagnostic capabilities.)

- What makes Autel dealer scanners stand out from the competition? (Their precision, reliability, and user-friendly interfaces are key differentiators.)

- What is the typical lifespan of an Autel dealer scanner? (With proper care and maintenance, Autel scanners can last for many years.)

- Are Autel dealer scanners compatible with all vehicle makes and models? (Autel offers a range of scanners with varying compatibility, so research is essential to find the right model.)

“The consistent performance and reliability of Autel scanners are a testament to their robust manufacturing process,” adds Maria Garcia, Lead Technician at City Auto Services. “We rely on them daily to provide accurate diagnoses and efficient repairs for our customers.”

Need Help? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 276 Reock St, City of Orange, NJ 07050, United States. We offer 24/7 customer support.