Autel compression waveform overlay is a powerful diagnostic tool that allows mechanics to visualize the pressure changes within a cylinder during compression. Understanding and interpreting these waveforms can be instrumental in pinpointing a variety of engine issues, from worn piston rings to leaky valves. This guide dives deep into the intricacies of Autel’s compression waveform overlay, providing you with the knowledge to utilize this feature effectively.

Understanding the Basics of Compression Waveform Overlay

Compression waveform overlay on Autel scanners provides a visual representation of the pressure fluctuations inside the cylinder during the compression stroke. It essentially plots pressure against time, creating a distinct waveform that reflects the health of the cylinder’s components. By analyzing the shape, height, and other characteristics of the waveform, technicians can identify potential problems and diagnose engine issues more accurately. This is a crucial step towards efficient and effective repairs.

Why is Autel Compression Waveform Overlay Important?

Using this feature allows for a more precise diagnosis compared to traditional compression testing. It goes beyond simply measuring the peak pressure and provides insights into the dynamic behavior of the compression process. This allows mechanics to differentiate between various problems that might result in similar compression readings. Imagine being able to pinpoint a leaky valve versus worn piston rings with a single glance at the waveform – that’s the power of this technology.

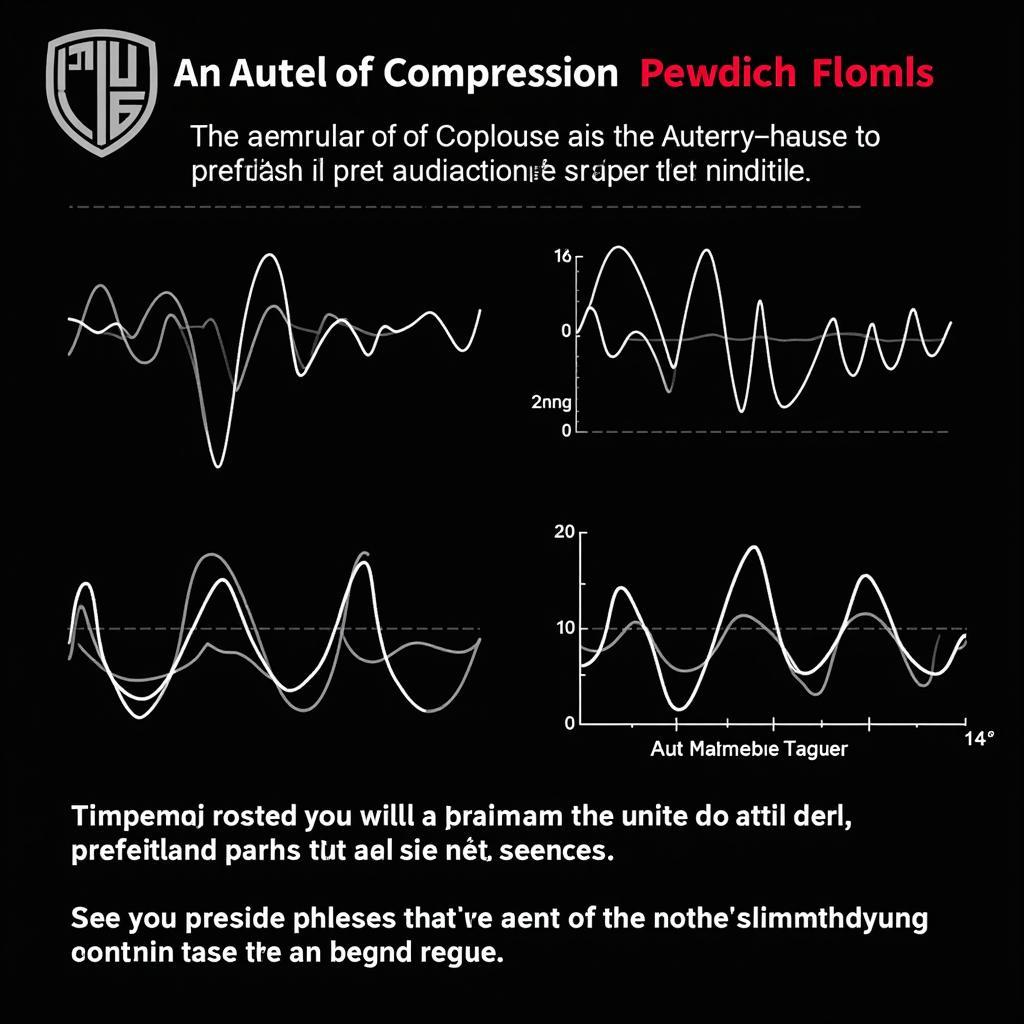

Interpreting Autel Compression Waveform Patterns

Different engine problems produce unique waveform patterns. Recognizing these patterns is key to accurate diagnosis. Let’s explore some common waveform anomalies and their associated issues.

- Low Peak Pressure: This indicates a general loss of compression and could point towards problems like worn piston rings, leaky valves, or a blown head gasket.

- Slow Pressure Rise: A slow rise in pressure might suggest restricted intake valves or issues with the camshaft timing.

- Sharp Pressure Drop: A sudden drop in the waveform could indicate a leaky valve or a damaged piston.

- Oscillations in the Waveform: Unusual oscillations might point towards problems with the valve train or other moving components within the cylinder.

Autel Compression Waveform Showing Low Peak Pressure

Autel Compression Waveform Showing Low Peak Pressure

Practical Applications of Compression Waveform Overlay

The Autel compression waveform overlay isn’t just a theoretical tool; it has numerous practical applications in everyday automotive diagnostics.

- Diagnosing Cylinder Leakage: Quickly identify the source of compression loss, whether it’s due to piston rings, valves, or the head gasket.

- Verifying Valve Timing: Confirm correct valve timing by analyzing the waveform’s shape and timing relative to crankshaft position.

- Evaluating Engine Performance: Use the waveform to assess the overall health and performance of individual cylinders and the engine as a whole.

- Troubleshooting Misfires: Identify the cylinder experiencing misfires and gain insights into the potential causes.

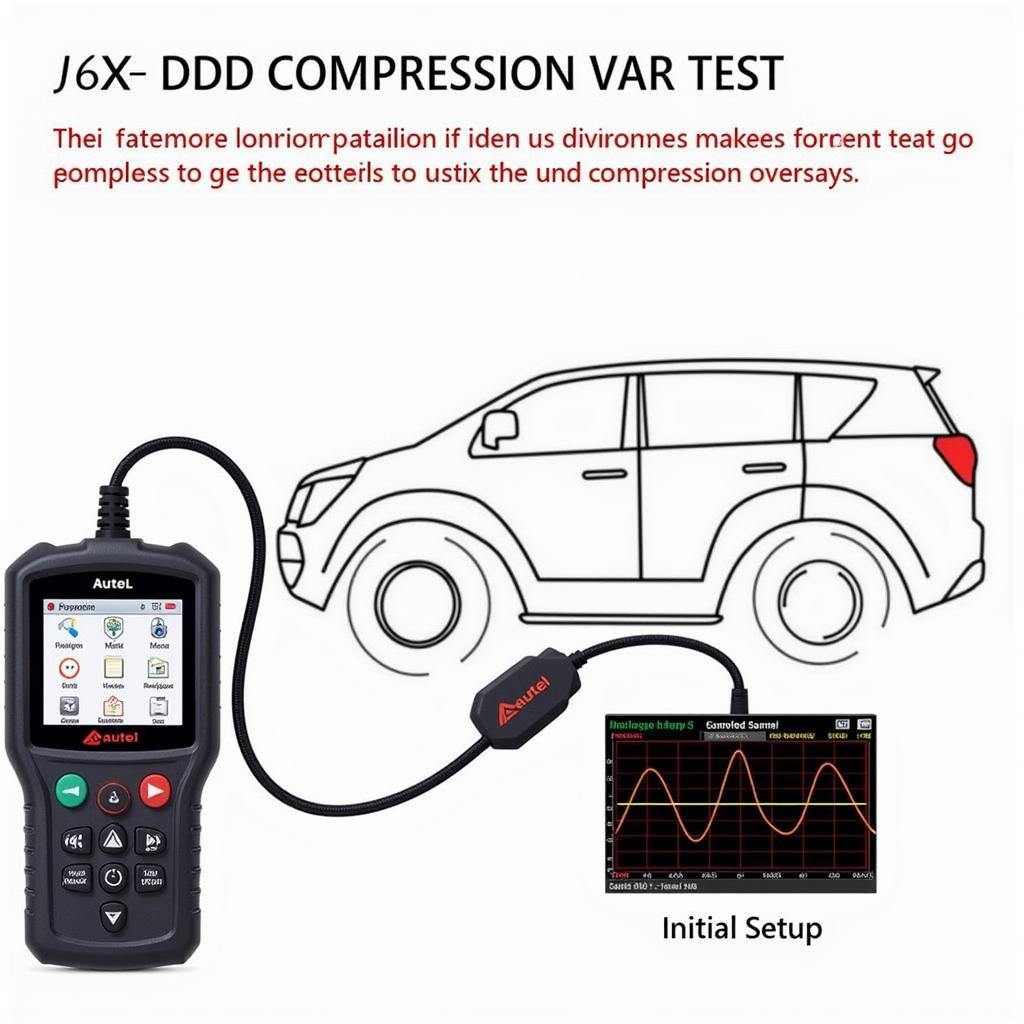

How to Use Autel Compression Waveform Overlay on Your Scanner

Using the compression waveform overlay feature on your Autel scanner is generally straightforward. However, specific steps might vary depending on the model. Consult your device’s user manual for detailed instructions. Typically, the process involves connecting the scanner to the vehicle’s diagnostic port, selecting the compression test function, and following the on-screen prompts.

Autel Scanner Connected to OBD Port for Compression Test

Autel Scanner Connected to OBD Port for Compression Test

Advanced Techniques and Tips

While the basics are relatively easy to grasp, mastering the Autel compression waveform overlay involves understanding some advanced techniques.

- Comparing Waveforms: Comparing waveforms between cylinders can reveal subtle differences and help pinpoint problematic areas.

- Using Overlay Feature: Overlaying waveforms from different tests allows for direct comparison and trend analysis.

- Considering Environmental Factors: Temperature and humidity can affect compression, so consider these factors when interpreting the waveforms.

“Understanding the nuances of the compression waveform is a game-changer for diagnostics,” says Michael Stevens, ASE Master Technician and automotive instructor. “It allows you to see the inner workings of the engine in a way that traditional methods simply can’t match.”

Conclusion

Autel compression waveform overlay is a valuable tool for any automotive technician. By understanding how to interpret these waveforms, you can diagnose engine problems more accurately and efficiently, saving time and money. Mastering this feature will undoubtedly enhance your diagnostic capabilities and improve the overall quality of your repairs, ensuring customer satisfaction and boosting your reputation as a skilled technician.

FAQ

- What is Autel compression waveform overlay? (A visual representation of cylinder pressure during compression.)

- How does it help in diagnostics? (It pinpoints issues like worn rings or leaky valves.)

- What are common waveform anomalies? (Low peak pressure, slow pressure rise, sharp drops.)

- How do I use this feature? (Connect the scanner, select the compression test, follow prompts.)

- Where can I find more information? (Consult your Autel scanner’s user manual.)

- What are some advanced techniques? (Comparing waveforms, using overlay feature, considering environmental factors.)

- Why is it important to master this feature? (For more accurate diagnoses and efficient repairs.)

Need assistance with your Autel scanner or have further questions about compression waveform overlay? Our team of experts is here to help 24/7. Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 276 Reock St, City of Orange, NJ 07050, United States.