3D scanning reverse engineering tools are revolutionizing industries by enabling the creation of digital models from physical objects. This powerful technology bridges the gap between the physical and digital worlds, offering a range of benefits from product development and quality control to historical preservation and artistic replication. This guide explores the intricacies of 3D scanning for reverse engineering, helping you understand its applications, advantages, and how to choose the right tools.

What are 3D Scanning Reverse Engineering Tools?

3D scanning reverse engineering tools combine the power of 3D scanning technology with specialized software to capture the precise geometry and dimensions of a physical object. This data is then used to create a digital 3D model, essentially reversing the traditional engineering design process. This allows for the analysis, modification, and reproduction of existing parts, even if original design data is unavailable. These tools empower professionals in various fields, offering unique opportunities for innovation and problem-solving.

Imagine having a broken part with no blueprints or CAD files. With 3D scanning reverse engineering, you can quickly create a digital replica, analyze the failure point, and produce a replacement part—even improving the original design in the process. This capability is invaluable in sectors like manufacturing, automotive, and aerospace, where dealing with legacy parts is a common challenge.

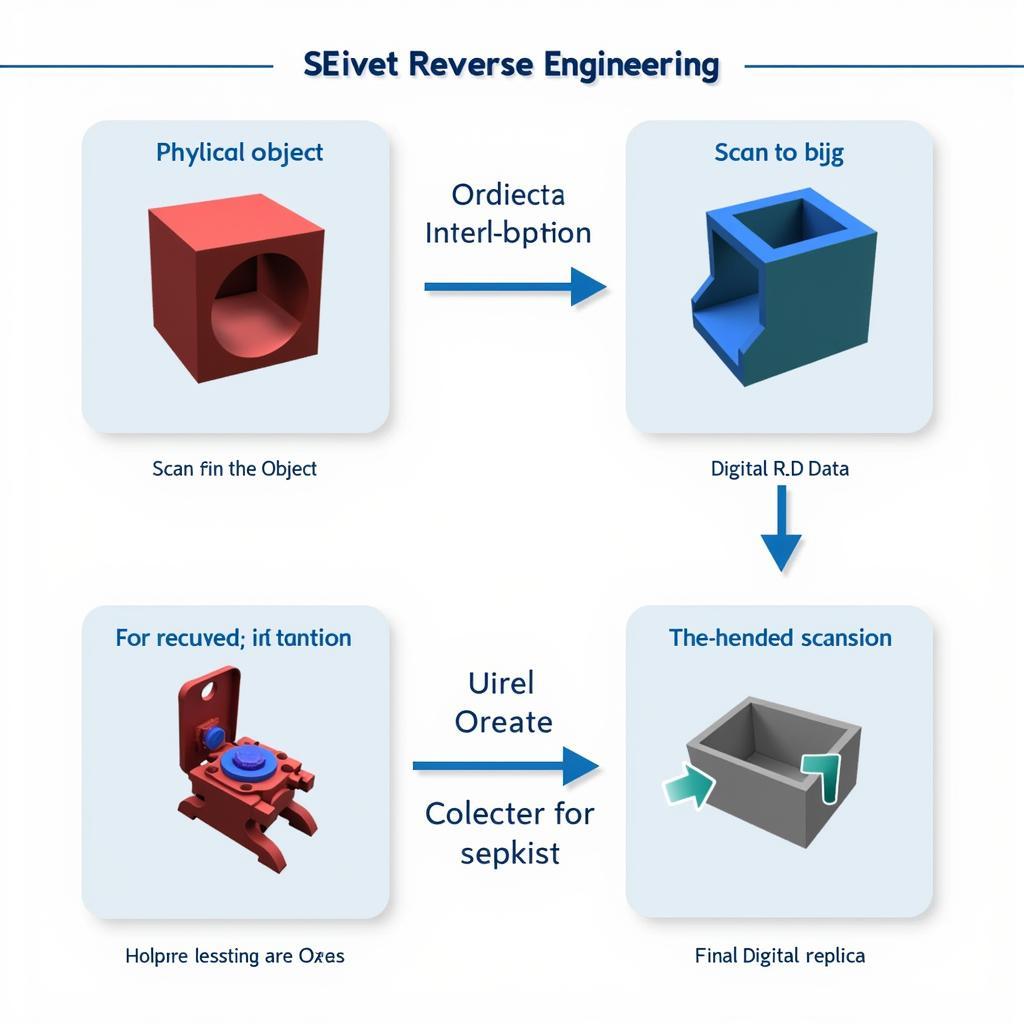

3D Scanning Reverse Engineering Process: A step-by-step visualization of the process from physical object to digital model, showcasing the technology and software involved.

3D Scanning Reverse Engineering Process: A step-by-step visualization of the process from physical object to digital model, showcasing the technology and software involved.

Benefits of Using 3D Scanning for Reverse Engineering

The advantages of using 3D scanning for reverse engineering are numerous, providing significant value across diverse industries:

- Rapid Prototyping: Quickly create prototypes from existing parts, accelerating product development cycles.

- Legacy Part Reproduction: Recreate parts for obsolete equipment without requiring original design files.

- Quality Control and Inspection: Compare scanned models to original CAD data to identify deviations and ensure quality.

- Cost Savings: Reduce design and manufacturing costs by streamlining the reverse engineering process.

- Improved Design: Analyze existing parts to identify weaknesses and implement improvements in new designs.

- Archiving and Preservation: Create digital records of historical artifacts or delicate objects for future generations.

These benefits translate to increased efficiency, reduced downtime, and greater design flexibility for businesses.

Choosing the Right 3D Scanning Reverse Engineering Tool

Selecting the appropriate tool depends on several factors:

- Accuracy and Resolution: The level of detail required for the digital model.

- Object Size and Complexity: The physical characteristics of the object being scanned.

- Portability and Ease of Use: The practicality of using the scanner in different environments.

- Software Compatibility: The ability to integrate the scanned data with existing CAD software.

- Budget: The overall cost of the scanning system and software.

Carefully considering these factors will ensure you choose a 3D scanning reverse engineering tool that meets your specific needs and delivers optimal results.

How Does 3D Scanning Compare to Traditional Reverse Engineering Methods?

Traditional methods of reverse engineering often involve manual measurements and painstaking CAD modeling, a time-consuming and error-prone process. 3D scanning dramatically accelerates this process, capturing accurate data in a fraction of the time. This translates to significant cost savings and faster turnaround times, making 3D scanning a highly efficient alternative.

“The precision and speed offered by 3D scanning are unparalleled. It’s a game-changer for reverse engineering,” says Dr. Amelia Carter, Lead Engineer at Advanced Manufacturing Solutions. “We’ve seen significant improvements in our workflow and the quality of our final products since incorporating 3D scanning into our processes.”

Future Trends in 3D Scanning Reverse Engineering

The field of 3D scanning reverse engineering is constantly evolving, with advancements in technology driving innovation and opening up new possibilities. Emerging trends include:

- Increased Automation: Automating the scanning and modeling process to further improve efficiency.

- Improved Software Integration: Seamlessly integrating scanning data with various CAD and design software.

- AI-Powered Analysis: Utilizing artificial intelligence to analyze scanned data and identify potential design flaws.

- Wider Accessibility: Making 3D scanning technology more affordable and accessible to a broader range of users.

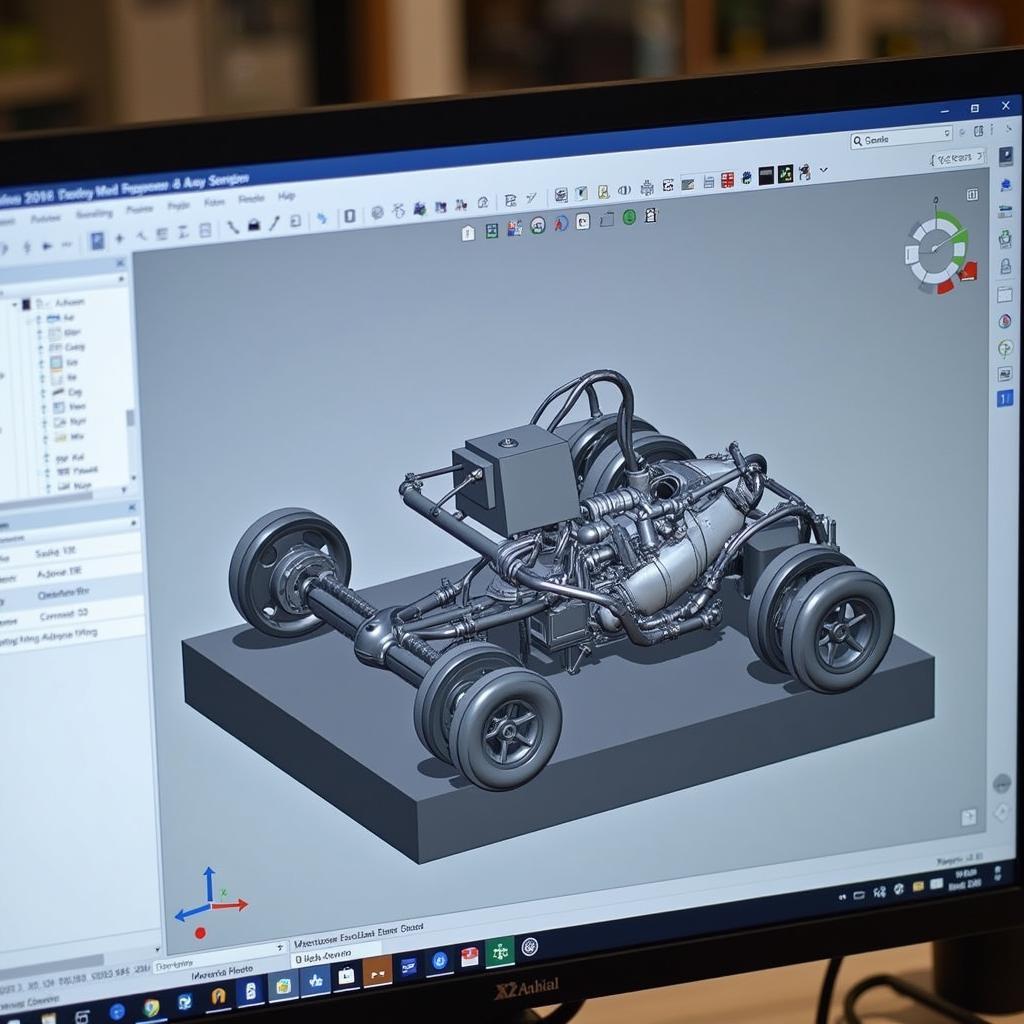

3D Model on Computer Screen: A detailed 3D model displayed on a computer monitor after being created using 3D scanning reverse engineering software.

3D Model on Computer Screen: A detailed 3D model displayed on a computer monitor after being created using 3D scanning reverse engineering software.

Conclusion

3D scanning reverse engineering tools are transforming the way products are designed, manufactured, and maintained. From streamlining prototyping to enabling the reproduction of legacy parts, these tools offer a powerful solution for various industries. By understanding the capabilities and benefits of 3D scanning reverse engineering, businesses can unlock new levels of efficiency, innovation, and competitive advantage. Understanding your needs and the different available options will help you select the perfect 3d scanning reverse engineering tool for your projects.

FAQ

- What file formats can 3D scanning reverse engineering tools output?

- How accurate are 3d scanning reverse engineering tools?

- What are the typical costs associated with 3d scanning reverse engineering?

- Can 3d scanning reverse engineering tools be used on any type of material?

- What are the limitations of 3d scanning reverse engineering?

- How much training is required to use 3d scanning reverse engineering tools effectively?

- What industries benefit the most from using 3d scanning reverse engineering?

Need more information on specific applications? Explore our article on 3d scanning tool for tablets.

For support, contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 276 Reock St, City of Orange, NJ 07050, United States. We offer 24/7 customer support.