Have you ever been about to diagnose your European car, only to find your trusty PT W2977 8 wire scan tool rendered useless because the wires broke off the plug? This frustrating situation is more common than you think, particularly with older scan tools that have seen their fair share of use.

This article will delve into the world of the PT W2977, explore why those pesky wires break, and most importantly, guide you through possible solutions and preventative measures.

Understanding the PT W2977 and its Fragile Wires

The PT W2977 is a familiar tool for many mechanics specializing in European vehicles, particularly older models from brands like BMW, Mercedes-Benz, Audi, and Volkswagen. Its 8-wire configuration allows for communication with various control modules, providing vital diagnostic information.

Why the Wires Break

The wires on the PT W2977 are often the weakest link, susceptible to breaking due to:

- Wear and Tear: Repeated bending, twisting, and pulling take their toll, especially at connection points.

- Poor Handling: Dropping the tool or yanking the cable can put excessive stress on the wires.

- Corrosion: Exposure to moisture or harsh chemicals can corrode the wires and weaken them.

- Poor Quality Materials: Some aftermarket cables may use inferior materials, making them more prone to breakage.

The Frustration of a Broken Scan Tool

Imagine this: your cherished Mercedes-Benz E-Class, parked on a bustling street in Los Angeles, suddenly refuses to start. You grab your PT W2977 to scan for error codes, only to discover the dreaded broken wires. Frustrating, isn’t it?

This scenario highlights the importance of understanding how to deal with this common issue.

Troubleshooting and Solutions

Before you toss your PT W2977 in despair, here are some potential solutions:

1. Visual Inspection:

- Check for Breaks: Carefully examine the entire length of the cable, focusing on the areas near the connectors, for any visible breaks or fraying.

- Inspect Connectors: Ensure the pins inside the connectors are straight and undamaged.

2. Testing for Continuity:

Use a multimeter to test for continuity between the pins on the plug and the corresponding wires. This will help pinpoint the location of the break.

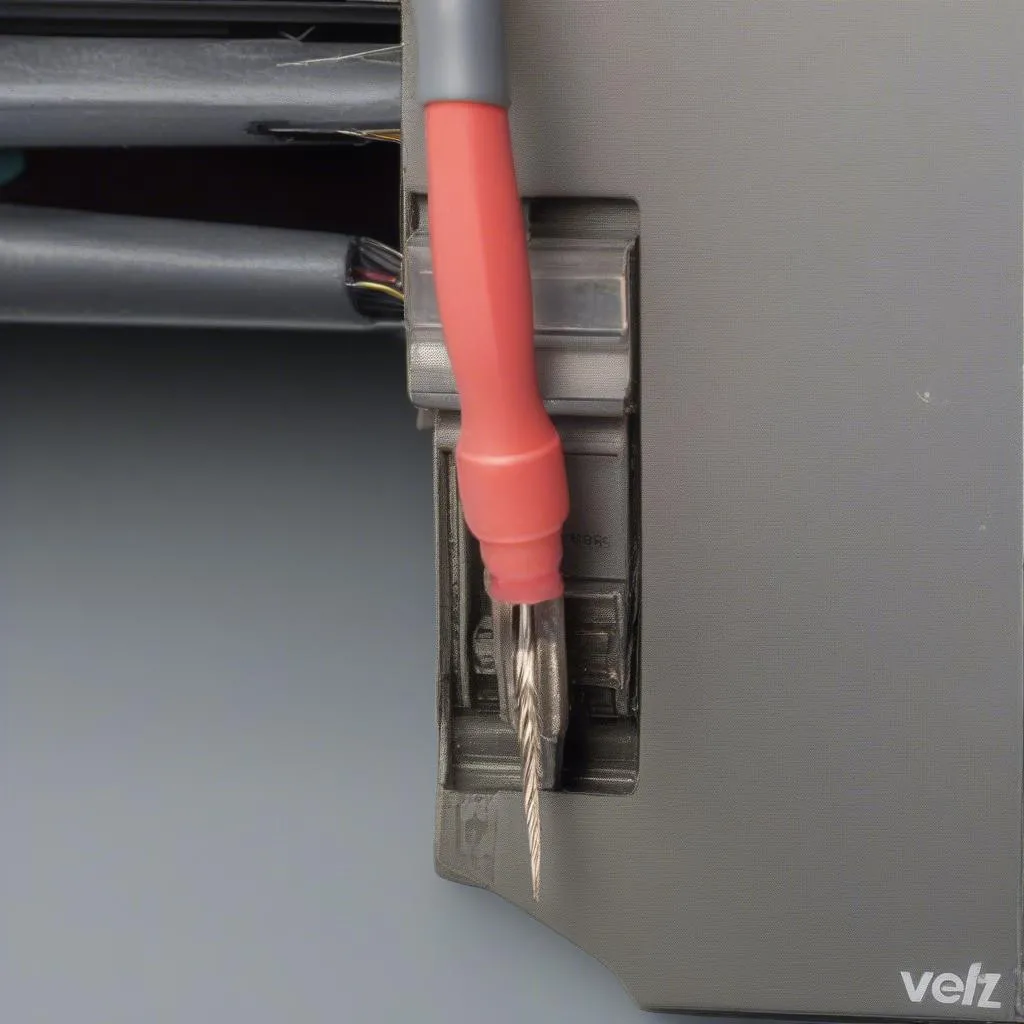

Broken wire on a PT W2977 scan tool

Broken wire on a PT W2977 scan tool

3. Repair Options:

- Soldering: If you’re comfortable with soldering, you can attempt to repair the broken wires. However, this requires precision and the right tools.

- Replacement Cable: The most straightforward solution is often to replace the entire cable. Ensure you purchase a high-quality replacement specifically designed for the PT W2977.

Replacement cable for a PT W2977 scan tool

Replacement cable for a PT W2977 scan tool

Preventative Measures

While troubleshooting broken wires can be frustrating, preventative measures can minimize the risk of future issues:

- Handle with Care: Avoid dropping the tool or yanking the cable.

- Regular Inspection: Visually inspect the cable regularly for signs of wear and tear.

- Proper Storage: Store the scan tool in a dry, clean environment, protecting it from moisture and harsh chemicals.

- Invest in Quality: Choose high-quality scan tools and cables from reputable manufacturers.

By understanding the causes, potential solutions, and preventative measures, you can keep your PT W2977 scan tool functioning smoothly for years to come.